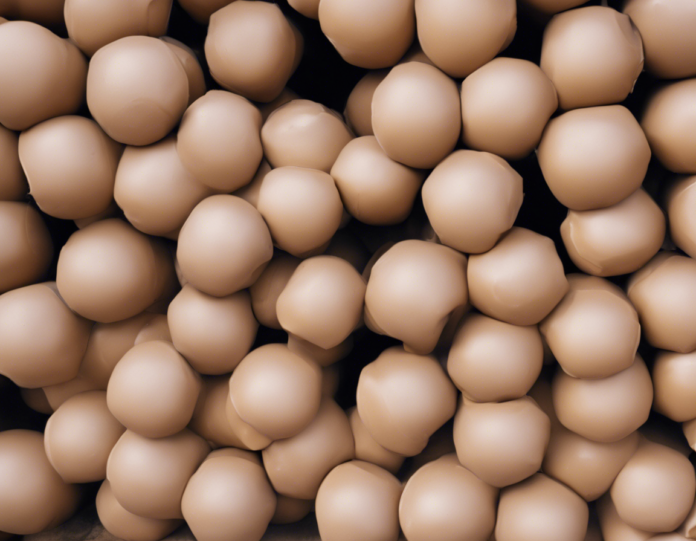

Natural rubber is a versatile material that has been used for centuries in various applications. It is a polymer of isoprene, a molecule composed of five carbon atoms arranged in a specific pattern. The unique chemical structure of natural rubber gives it its distinctive properties, making it an essential material in many industries.

What is Natural Rubber?

Natural rubber is a polymer made from the organic compound isoprene. It is extracted from the sap of the Hevea brasiliensis tree, also known as the rubber tree. The process of harvesting natural rubber involves tapping the tree to collect the latex sap, which is then processed to remove impurities and dried to form solid rubber sheets.

Properties of Natural Rubber

Natural rubber exhibits several unique properties that make it a valuable material in various applications:

1. Elasticity

Natural rubber is known for its excellent elasticity, allowing it to stretch and return to its original shape. This property makes it ideal for applications requiring flexibility and resilience.

2. Strength

Despite its elasticity, natural rubber is also strong and durable. It can withstand repeated stretching and compression without deforming or breaking.

3. Abrasion Resistance

Natural rubber has high resistance to abrasion, making it suitable for use in applications where the material is subjected to friction or wear.

4. Low Temperature Flexibility

Natural rubber remains flexible at low temperatures, making it useful in cold climates or applications requiring flexibility in sub-zero conditions.

5. Water Resistance

Natural rubber is inherently water-resistant, making it an excellent choice for applications where exposure to moisture is a concern.

Applications of Natural Rubber

Natural rubber is used in a wide range of applications across various industries, including:

1. Tires

One of the most common uses of natural rubber is in tire manufacturing. Its elasticity and strength make it ideal for creating durable and reliable tires for vehicles of all types.

2. Industrial Belts and Hoses

Natural rubber is used to manufacture belts and hoses for industrial machinery and equipment, where flexibility and strength are essential.

3. Footwear

Many types of footwear, including sneakers, boots, and sandals, are made from natural rubber due to its comfortable and resilient properties.

4. Seals and Gaskets

Natural rubber is used to create seals and gaskets for airtight and watertight applications, such as in automotive engines and plumbing systems.

5. Industrial Rollers

Natural rubber is also used to make rollers for industrial machinery, providing a gripping surface that can withstand wear and tear.

Synthetic Rubber vs. Natural Rubber

While natural rubber has many advantageous properties, synthetic rubber has gained popularity due to its specific characteristics and cost-effectiveness. Synthetic rubber is produced through chemical processes using petroleum-based raw materials, whereas natural rubber is derived from the latex sap of rubber trees.

Key differences between synthetic rubber and natural rubber include:

- Cost: Synthetic rubber is often cheaper to produce than natural rubber, making it a more cost-effective option for many manufacturers.

- Properties: Synthetic rubber can be engineered to have specific properties, such as enhanced durability or chemical resistance, that may not be found in natural rubber.

- Sustainability: Natural rubber is a renewable resource, while synthetic rubber relies on non-renewable petroleum sources. However, natural rubber production can have environmental impacts, such as deforestation.

While both types of rubber have their advantages and drawbacks, the choice between natural rubber and synthetic rubber depends on the specific requirements of the application and considerations such as cost, performance, and sustainability.

Environmental Impact of Natural Rubber Production

While natural rubber is a renewable resource, its production can have environmental consequences, particularly in regions where rubber plantations contribute to deforestation and habitat loss. Sustainable rubber production practices aim to mitigate these impacts by promoting responsible land management, conservation, and fair labor practices within the rubber industry.

Ways to promote sustainable natural rubber production include:

- Forest Protection: Preserving natural habitats and biodiversity by avoiding deforestation for rubber plantations.

- Agroforestry: Introducing rubber trees in mixed crops or forests to promote biodiversity and reduce environmental impact.

- Certification Programs: Supporting certifications like the Forest Stewardship Council (FSC) or the Roundtable on Sustainable Palm Oil (RSPO) to promote environmentally and socially responsible rubber production.

Sustainable natural rubber production is essential to minimize the environmental impact of rubber cultivation and ensure the long-term viability of the rubber industry.

Frequently Asked Questions (FAQs)

Q1: Is natural rubber biodegradable?

A1: Yes, natural rubber is biodegradable, as it is derived from plant sources and can decompose over time.

Q2: Can natural rubber be recycled?

A2: Yes, natural rubber can be recycled by shredding or grinding used rubber products to create new materials or by reusing rubber in various applications.

Q3: What is vulcanized rubber?

A3: Vulcanized rubber is natural or synthetic rubber that has been treated with sulfur or other additives to improve its strength, elasticity, and durability.

Q4: Is natural rubber suitable for food-grade applications?

A4: Yes, natural rubber is often used in food-grade applications such as seals, gaskets, and conveyor belts due to its non-toxic properties.

Q5: How can I differentiate between natural rubber and synthetic rubber products?

A5: Natural rubber products often have a distinct smell and texture compared to synthetic rubber products, which may feel smoother and less organic.

In conclusion, natural rubber is a valuable and versatile material with a wide range of applications in various industries. Its unique properties, such as elasticity, strength, and water resistance, make it an essential component in products ranging from tires to footwear. While synthetic rubber offers distinct advantages, natural rubber remains a renewable and sustainable choice for many applications when produced using environmentally responsible practices.