Printed Circuit Board: The Foundation of Modern Electronics

Introduction

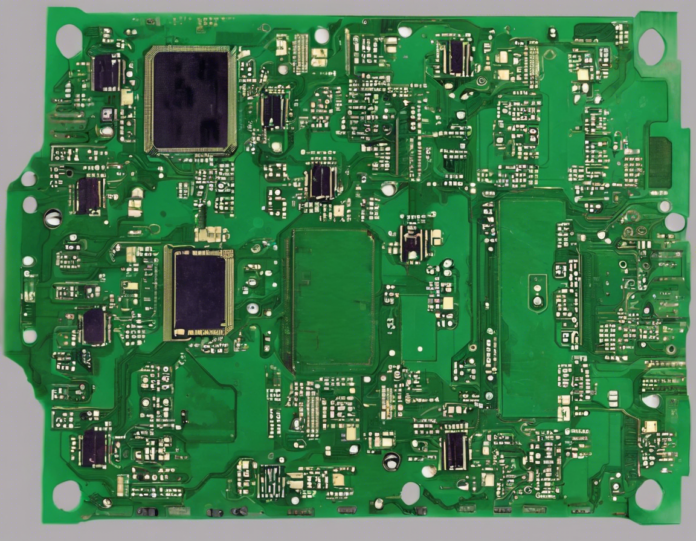

Printed Circuit Boards (PCBs) are the heart and soul of modern electronics, serving as the foundation on which most electronic devices are built. Whether it’s a smartphone, a computer, a television, or a medical device, chances are that a PCB is at the core of its functionality. In this comprehensive guide, we will delve deep into the world of PCBs, exploring what they are, how they work, their various types, the manufacturing process, and their crucial role in shaping the technological landscape we live in today.

What is a PCB?

A Printed Circuit Board (PCB) is a flat board made of non-conductive material, such as fiberglass, with conductive pathways etched or “printed” onto the board. These conductive tracks, typically made of copper, serve as connections for various electronic components like integrated circuits (ICs), resistors, capacitors, and more. The design of these circuits is crucial as it dictates how the electronic device will function.

How Does a PCB Work?

The functionality of a PCB revolves around the concept of allowing the flow of electricity between different components to perform specific operations. The copper tracks on the board act as wires between components, creating a path for electric currents to travel. By strategically placing components and designing the circuit layout, engineers can ensure that electricity flows in the right direction, enabling the device to function as intended.

Types of PCBs

There are several types of PCBs, each serving different purposes based on the requirements of the electronic device. Some common types include:

Single-sided PCBs: These are the simplest type of PCB, with components mounted on one side of the board only.

Double-sided PCBs: These have components mounted on both sides of the board, connected through plated through-holes or vias.

Multi-layer PCBs: These PCBs have more than two layers of conductive material separated by insulating layers, allowing for complex and dense circuit designs.

Rigid PCBs: The standard type of PCB that is rigid and cannot be bent or twisted.

Flexible PCBs: These PCBs are made of flexible materials like polyimide, allowing them to be bent or twisted to fit into compact spaces.

Rigid-Flex PCBs: A combination of rigid and flexible PCBs, offering the benefits of both types in one design.

PCB Manufacturing Process

The manufacturing of PCBs is a meticulous process that involves several steps, including:

1. Design: Engineers use specialized software to design the layout of the PCB, including component placement and track routing.

2. Substrate Preparation: The non-conductive substrate material, often fiberglass, is cut into the required size and shape.

3. Copper Cladding: A thin layer of copper is laminated onto the substrate to form the conductive layer.

4. Etching: Chemical etching or milling is used to remove the excess copper and define the conductive tracks according to the design.

5. Drilling: Small holes are drilled into the board to create vias for connecting different layers of the PCB.

6. Component Mounting: Electronic components are soldered onto the board using specialized equipment.

7. Testing: The finished PCB undergoes rigorous testing to ensure proper functionality and reliability.

Role of PCBs in Technology

PCBs play a critical role in the miniaturization, efficiency, and functionality of electronic devices. Without PCBs, the complex circuits in modern electronics would be cumbersome and unreliable. The compact nature of PCBs allows for smaller and more portable devices, while their standardized design streamlines the manufacturing process and reduces costs.

FAQs:

Q1: What does PCB stand for?

A1: PCB stands for Printed Circuit Board.

Q2: What are the main components of a PCB?

A2: The main components of a PCB include integrated circuits (ICs), resistors, capacitors, diodes, transistors, and connectors.

Q3: Why are PCBs made of fiberglass?

A3: Fiberglass is a popular material for PCBs due to its non-conductive properties, durability, and heat resistance.

Q4: How do I design a PCB layout?

A4: PCB layouts are designed using specialized software like Eagle, Altium Designer, or KiCad, where you can place components, route tracks, and generate manufacturing files.

Q5: Can PCBs be recycled?

A5: Yes, PCBs can be recycled to recover valuable materials like copper, gold, and silver, while also minimizing electronic waste.

In conclusion, Printed Circuit Boards are the unsung heroes of the electronic world, enabling the devices we rely on daily to function efficiently and reliably. Understanding the importance of PCBs and their intricate design and manufacturing processes sheds light on the remarkable technology that powers our modern world.